THE DRIPSTOP™ TECHNOLOGY

The condensation problem in non-climate controlled buildings

Metal roofs cool quickly at night or in cold weather. Warm, moist interior air reaching the dew point condenses on the underside of the sheet and drips onto people, equipment, or livestock. Dripstop tackles that right at the source.

What Dripstop is

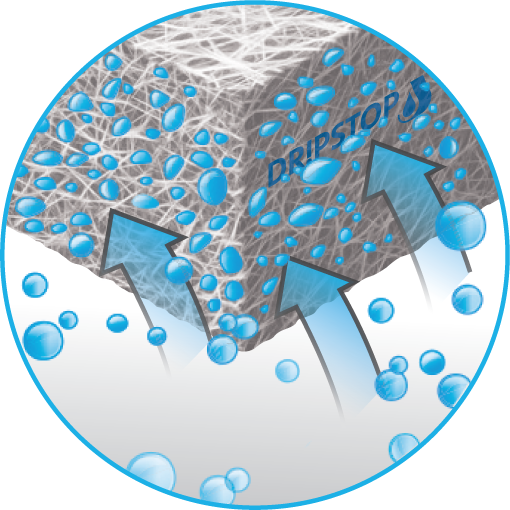

Dripstop is a high-performance anti-condensation membrane designed to control and manage condensation on the underside of uninsulated metal roofing systems. It consists of a high-tech, nonwoven polymer (often PES) membrane that is factory-applied or prefabricated as part of the roofing panel system. The membrane absorbs moisture (condensation) at the point of formation, holds it within its structure, and then releases it back into the air as humidity when conditions return above the dew point — thereby preventing water droplets from forming and dripping into the building interior.

Core mechanism

- Absorption: The membrane captures condensate that would otherwise bead and fall.

- Temporary storage of moisture: It holds the water ian its fiber matrix instead of letting droplets form and drip.

- Resetting/drying: As temperature and ventilation improve, the stored moisture evaporates back into the air, “preparing” the membrane for the next cycle.

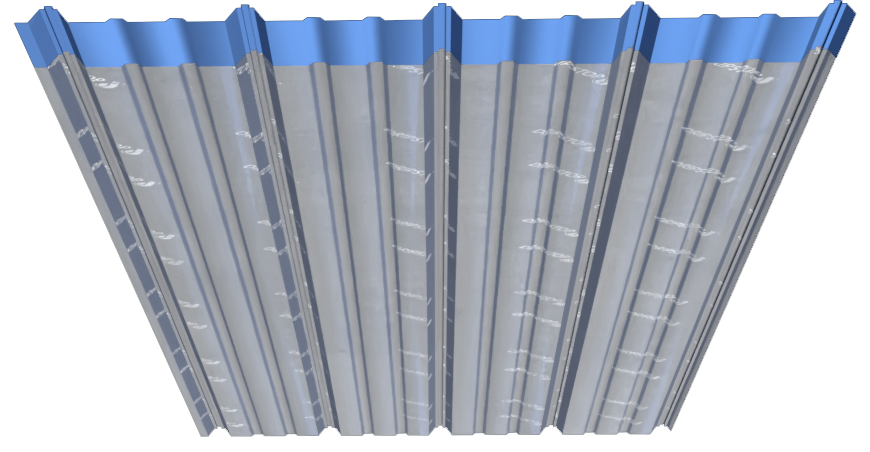

Installation & integration

- The Dripstop membrane is applied at the roofing panel manufacturer, not on site—so coverage is uniform and consistent.

- Roofers install panels normally, no extra labor is required. Eaves require glazing to avoid wicking after installation.

- Can eliminate the need for traditional insulation making roof installation faster and safer.

Performance benefits

- Drip control: Keeps interiors dry by preventing environmental humidity from forming drops and falling.

- Metal roof panel protection: Acts as a barrier layer between metal and condensate, helping reduce moisture contact, corrosion and the risks that come with it.

- Cost & simplicity: Often replaces complicated underlayments or insulated sandwich panels where thermal performance isn’t the goal—reducing parts and labor.

- Durability: The non-woven membrane will not rip or tear like traditional insulation/vapor barrier and is resistant to pest, birds and rodents.

- Acoustic comfort: The membrane layer provides measurable sound damping (a quieter interior than bare metal). Up to 20% reduction in impact noise (rain) and reflective acoustics (echo).

Design/usage notes

- Works across agricultural, storage, workshops, and other single-skin metal buildings where condensation cycles are common.

- As with any building, plan for ventilation (ridge/soffit or mechanical) so the membrane can dry out between cycles. Proper airflow is part of the system’s effectiveness.

Maintenance

Because it’s bonded to the sheet, there’s no loose liner to sag or tear. Periodic building ventilation checks and general roof care are typically all that’s needed.